Food

LABELING, SLEEVING, MULTIPACKING, AND TRUSSING

Felins offers different industrial food packaging machines and processing solutions for companies in the food industry who are looking for an eco-friendly way to automatically label, sleeve, or multipack your products. Instead of using adhesives to secure labels or sleeves to your product, we apply them with tension and then use an ultrasonic weld to secure everything in place. We also offer a tying equipment to automatically truss rotisserie chickens reducing your labor requirements and repetitive injury occurrences associated with hand trussing.

ADHESIVE FREE LABELING

How is our premium labeling solution different than all of the other labels out there? There is one major difference…We don’t use adhesives to attach the label to your product. Instead we use tension to gently wrap the label around your product and then secure the label to itself using an ultrasonic weld. The result is a label that:

- Won’t stick to your product

- Stays in place

- Doesn’t use heat (ultrasonic welding is a cold process)

- Is easy to remove by your customer

- Looks great

- Never requires backing paper

- Doesn’t attract dirt or debris like adhesive labels tend to do

- Is fully recyclable

Our labeling solution is designed to work well on any kind of tray, skin packs, hot dog and sausage packs, produce and a variety of other products. Learn more here or by clicking on one of the Food Machinery sections at the bottom of this page.

AUTOMATIC SLEEVING

Similar to our premium labeling solution, we don’t use adhesives for paperboard sleeving. In fact, our sleeving is nearly identical to our labeling solution. The only difference is the use of a paperboard sleeve instead of a plastic film. Both are applied in the exact same manner and can use the same piece of equipment. Just like our labeling solution, we use tension to hold the sleeve onto your product and ultrasonically weld the sleeve to itself to hold it in place. Once applied, you don’t have to worry about the sleeve sliding off or using a glue dot to hold the sleeve in place.

Our sleeves are designed to work well on any kind of tray, skin packs, hot dog and sausage packs, and a variety of other products. Learn more here or by clicking on one of the Food Machinery sections at the bottom of this page.

PRODUCE PACKAGING

Paper and plastic banding machines provide attractive, sustainable packaging solutions for a variety of fresh produce. Using produce packaging is an effective way to extend produce shelf life and prevent physical damage during transportation. Our precise, gentle packaging technology ensures produce stays fresh and safe.

From sleeving English cucumbers to prevent moisture loss to packaging fresh apples in paper trays for added stability and protection, we offer a variety of efficient, eco-friendly produce packaging solutions to benefit growers, distributors, and consumers.

MULTIPACKING & CLUB PACKING

The same tensioning process that we use for our premium labeling and automatic sleeving works great for the creation of multipacks and club packs. The process of applying the label or sleeve is the same: wrap it around a group of products and ultrasonically seal it to itself and voila! You now have a product ready for sale at a club store. Our ability to precisely and gently apply the label or sleeve allows us to securely hold a group of products together without the use of adhesives.

We have fully automated solutions which can stack or group your products or you can manually create a stack and then apply the label or band. Learn more here or by clicking on one of the Food Machinery sections at the bottom of this page.

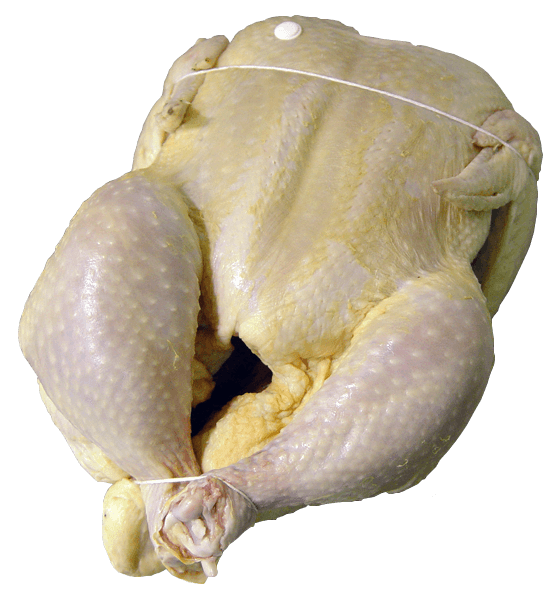

AUTOMATIC CHICKEN TRUSSING

We also offer equipment to automatically truss rotisserie chickens. Our company was founded in 1921 when our founder discovered a way to efficiently tie a string around sausages. We have been refining that design ever since and now use it to help truss chickens. When compared to manual trussing operations, our automated trussing solution increases throughput and reduces repetitive motion injuries. We have a variety of food grade elastics to meet a variety of unique trussing requirements.

Learn more here or by clicking on one of the Food Machinery sections at the bottom of this page.

Follow @FelinsFoodie on Twitter for updates from our Food Packaging Fanatic, Lisa!

Food Machinery

Want help identifying the sustainable packaging solution that is best for you?